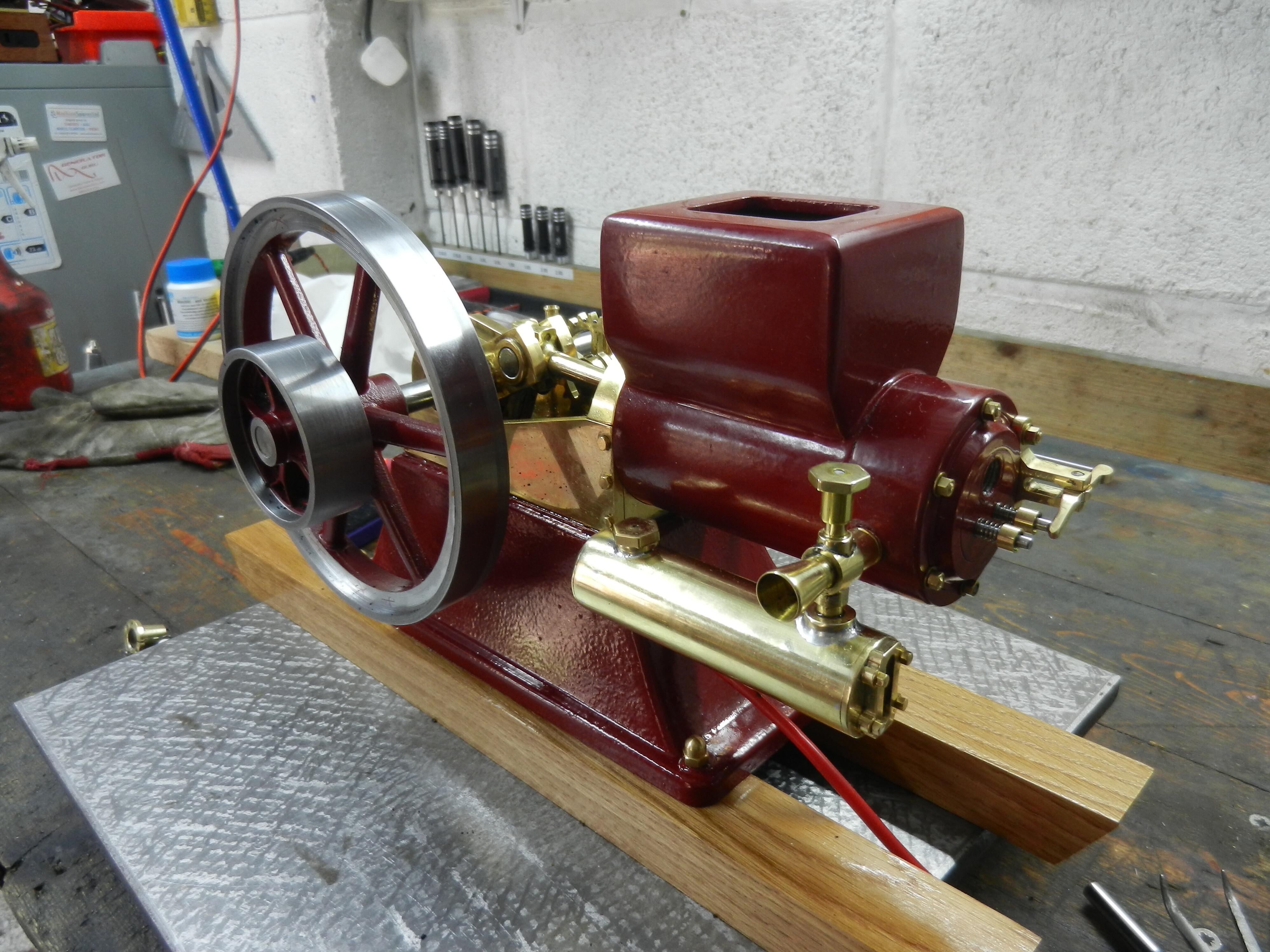

Getting close to finishing this thing now, got the water hopper finished and painted.

And wasted a pound of silver steel rod learning how to make long thin valve stems, still ended up with the stem finish of an old nail but at least the ridges are smooth and the stem parallel and a good fit.

The valves run direct in the aluminium head so i guess they will wear loose quickly, but i can always go back and add proper valve guides later.

The fuel tank is quite heavy and the carb design had it all hanging on a 4mm threaded piece of brass rod with a hole up the middle, seemed a bit weak to me, plus the plan had the jet (and tank) soldered into one half of the carb and a separate piece for the adjusting needle assy soldered opposite. After making the carb to the original design i decided to start over and redesign with a larger one piece jet assy. holding the tank with an M6 thread instead.

Finished carb

With tank ready to fit

Well after the pushrod guides were done, so fiddley, i was itching to see if it would run. Put some petrol oil mix in the tank and gave it a spin, it fired but the valves were seating poorly and did not have enough compression to keep running. This was not the worst though, the crank quickly started to run out of true and upon inspection i found the soft soldered joint to one side of the crankpin had loosened

If anyone has any advice they can give me on how to make a stronger crankshaft it would be gratefully recieved. In the meantime i have ordered a milling slide for the lathe (i don't have the money for a proper mill) and will be scratching my head trying to think of ways to make a more rigid crank, preferably without the soft solder.

Best wishes

Ade