Sunday, this is the day things usually go wrong, but never the less the cylinder head needs to be done.

First job was to make a mod to the lathe so can mark out 90 degrees and 60 degrees

So far so good

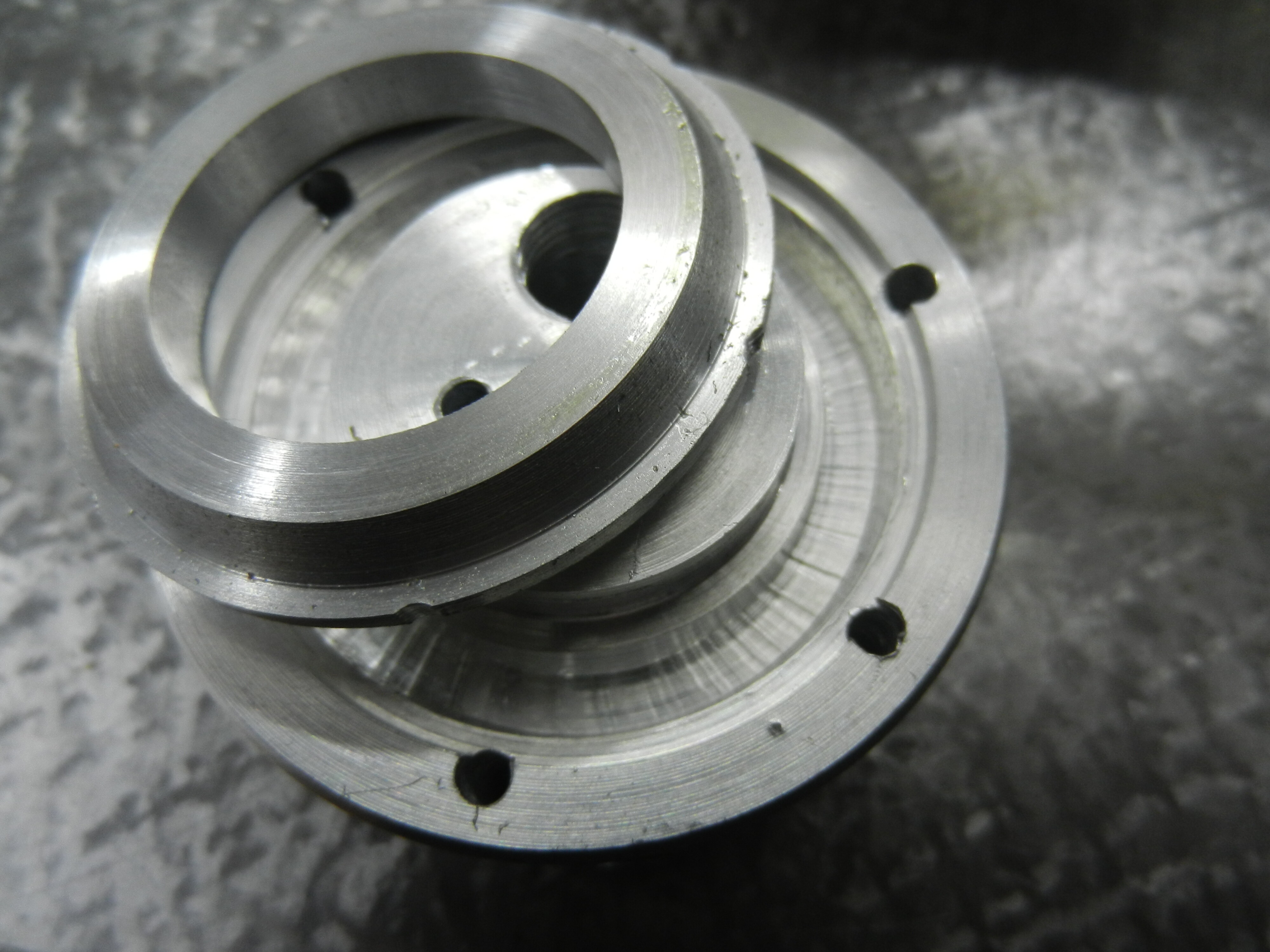

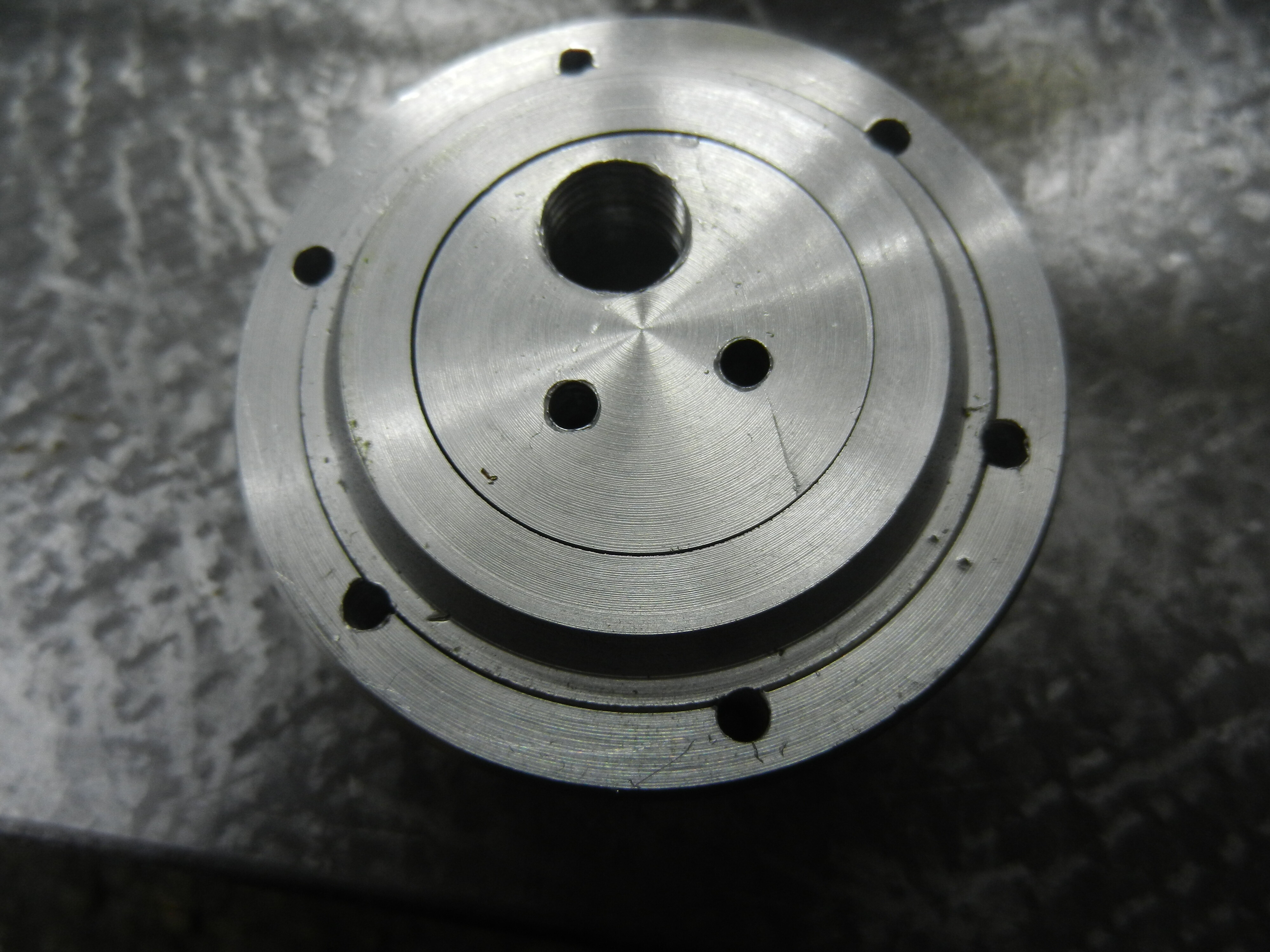

So the head could get some cooling i machined a water channel (complete with chatter marks) and a cover to seal it

Still retains the dimensions in the plans but was a tight squeeze

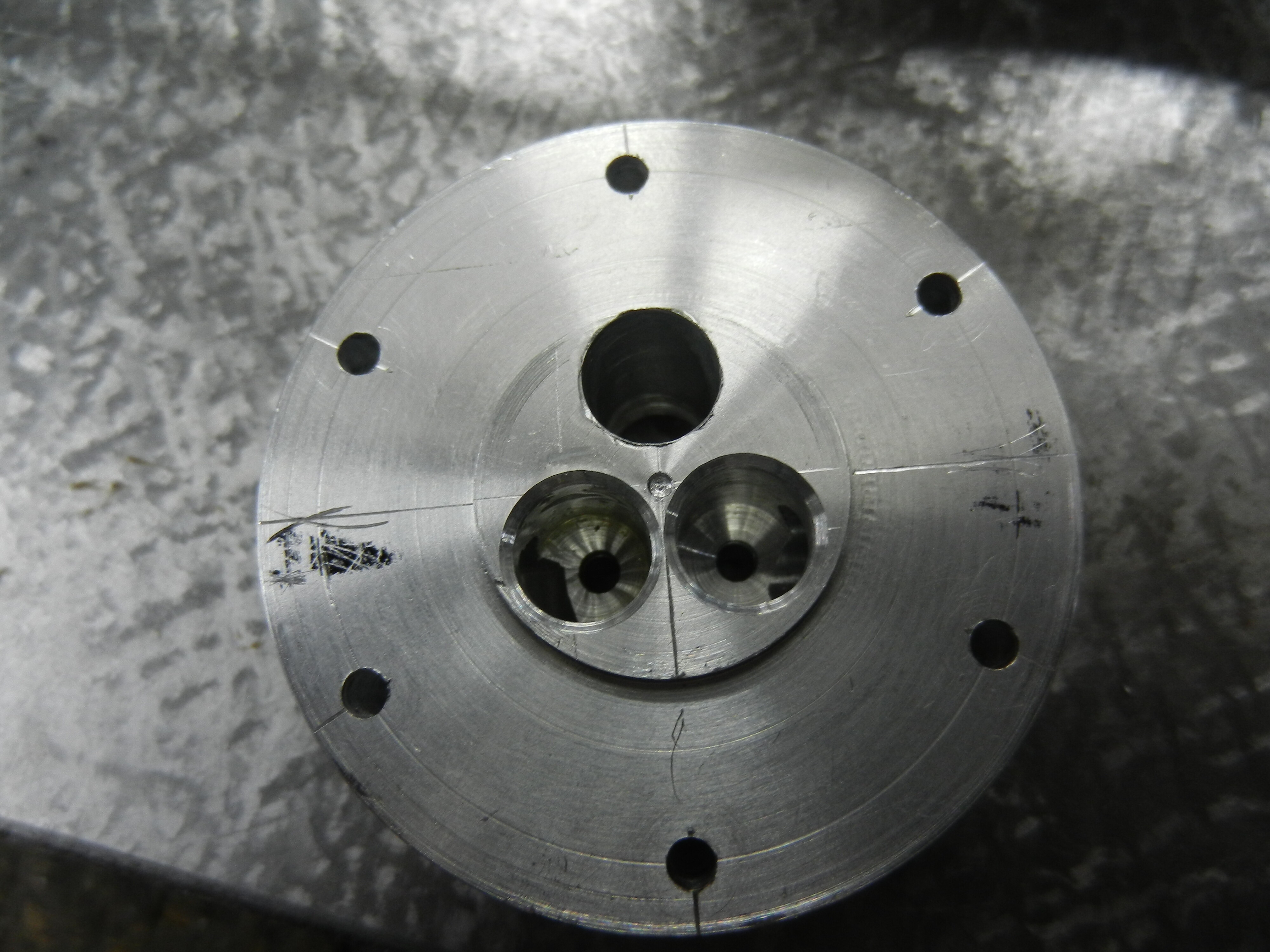

The valve seats, ports and plug were a tight fit in the space of the 25mm bore

Well the head went without a hitch, i think this project is teaching me to work more precisely and less slap dash

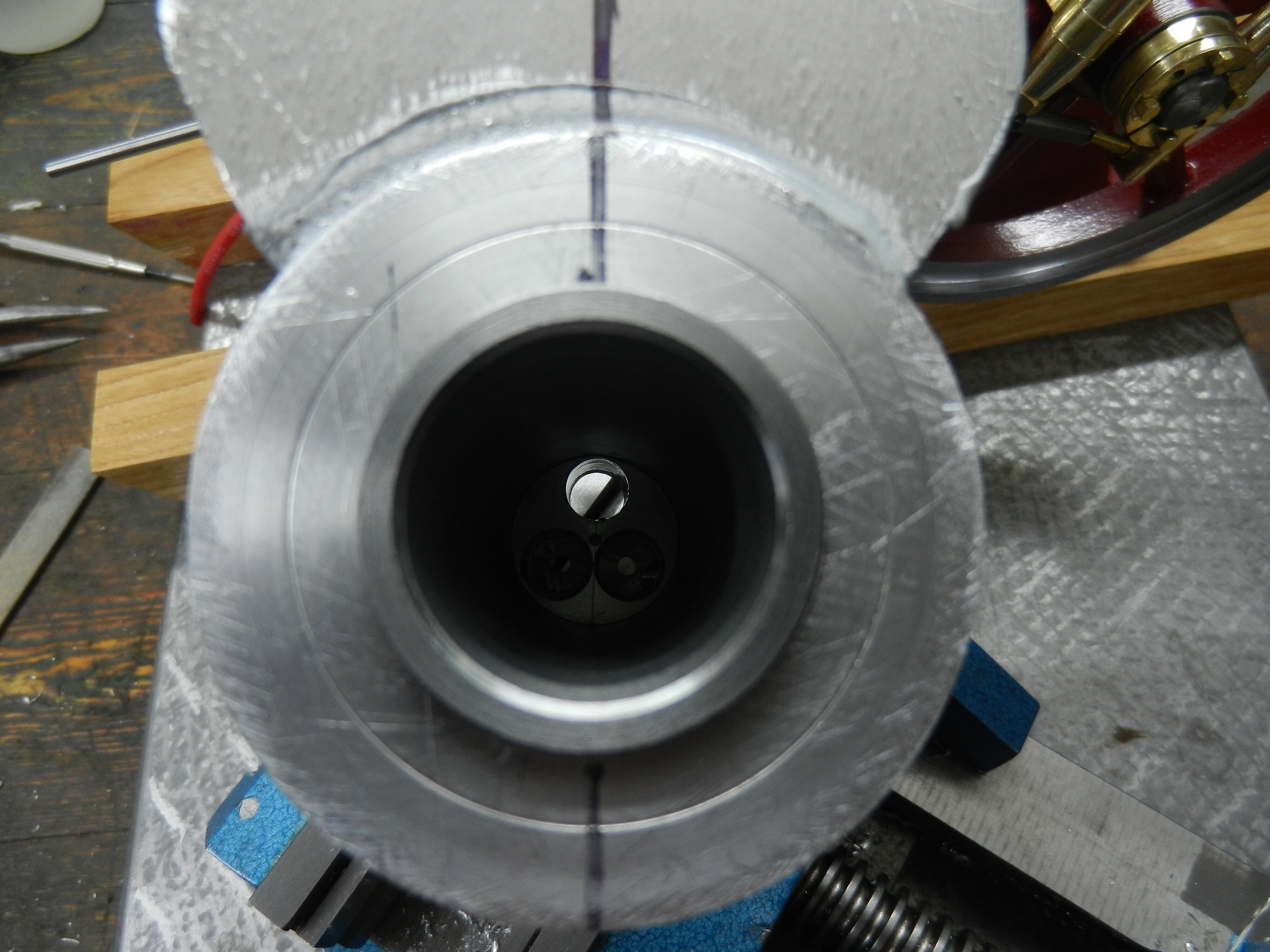

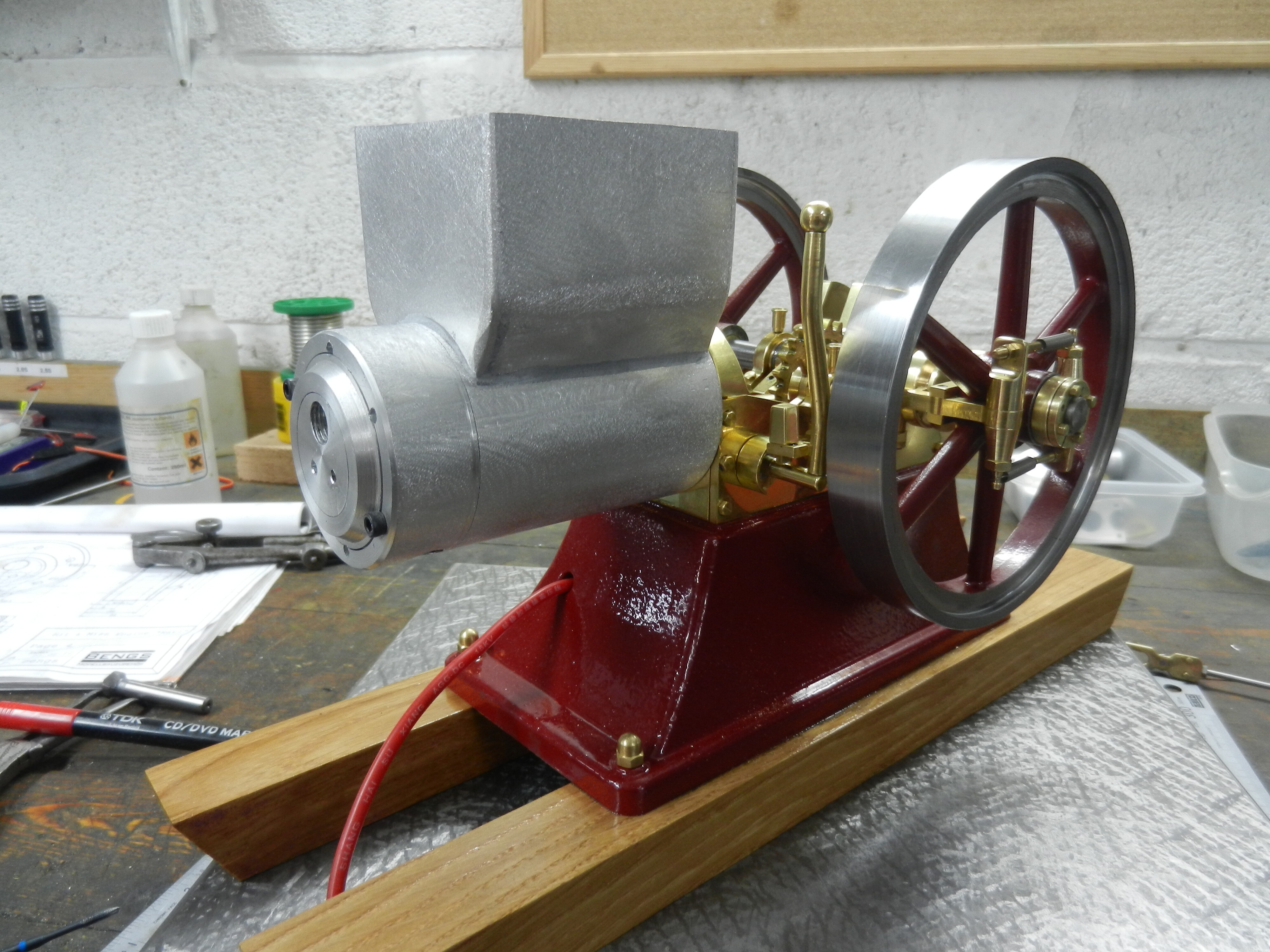

The Aluminium glue had dried so next step was to rough sand the water hopper, make a centering sleeve and fit the head and cylinder assy together and drill the holes to mount it all on the crankcase

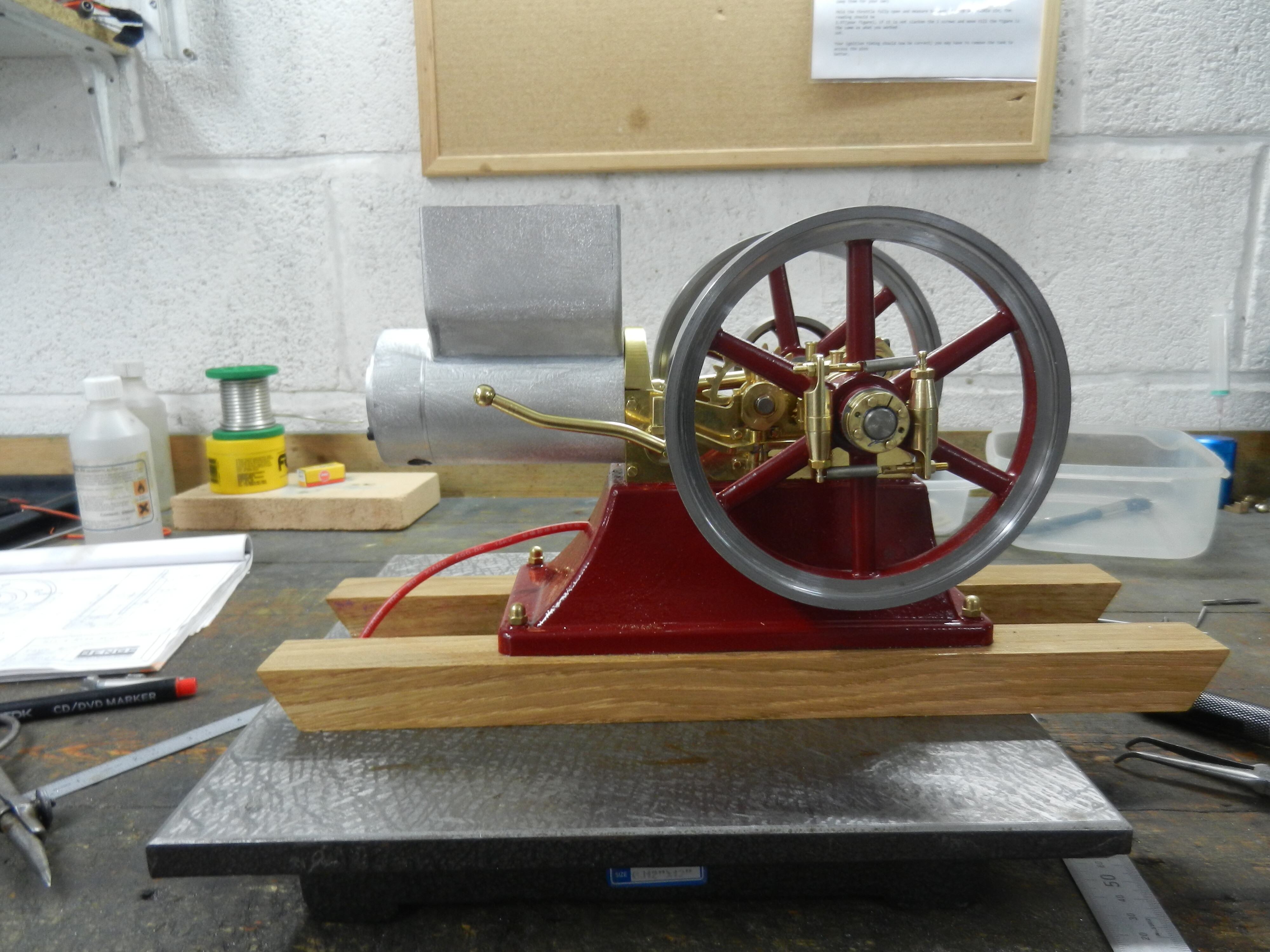

It ia actually looking like and engine for the first time

Everything fitted beautifully, the piston and rings fit well and make a nice crisp sound, the crank and rod do their job with no play or binding, feels like i'm getting somewhere now

Thanks for watching

Ade